| Materials | Price inc VAT | Lead Time |

|---|---|---|

| Oak | 7300 £ | 8 Weeks |

Out of stock

We Offer:

Oak staircases stay popular for their strength, beauty, and long-term reliability. When you know how each oak component works, you can choose a staircase that performs well and looks impressive. This guide explains every key oak staircase part and how each piece improves structure and appearance.

Oak treads carry daily foot traffic, so they must be strong. Our 50 × 250 mm solid oak treads are far larger and stronger than what many competitors use. This size gives better durability and stability. Each tread connects to the strings with proper tenons, allowing natural expansion without shifting.

Grooves may look useful, but they trap water, freeze in winter, and become slippery—so a flat, solid tread is always safer.

Risers close the vertical gaps between treads. They ensure no opening exceeds 100 mm, keeping the staircase safe and compliant. They also support each tread from behind, increasing stability and comfort.

The handrail guides users and shapes the overall design. Our solid 100 × 100 mm oak handrails, with 10 × 10 mm chamfered corners, are much larger than typical competitor sizes. Fully planed surfaces ensure strength, comfort, and a smooth, splinter-free finish.

Spindles support the handrail and create the staircase’s rhythm. We use 50 × 50 mm or 35 × 100 mm heavy oak spindles, much stronger than the thin versions many competitors offer.

All spindles use traditional mortise-and-tenon joints, allowing natural movement without loosening—unlike screws, which often crack or pull free over time.

The baserail supports the spindles and strengthens the balustrade. We always include a solid oak baserail, while some competitors remove it to cut costs.

Skipping the baserail leads to long-term issues such as weakened landing boards, cracking, shrinking, moisture damage, and deterioration. A proper baserail ensures durability and stability.

The string supports the treads and risers and transfers loads into the main posts. We use a minimum of 75 × 270 mm strings, much larger and stronger than standard competitor sizes.

They tenon into the main and newel posts with 35 mm thick, 70 mm long, and 170 mm high tenons, giving superior rigidity and structural performance.

The landing board ties the staircase into the building and spreads the load. We use a 32 × 150 mm unplaned solid oak landing board, thicker and wider than common alternatives. Smooth, groove-free surfaces avoid water traps, rot, and ice buildup, increasing lifespan and stability.

Main posts absorb forces from the landing and newel posts. We use large, heavy-duty solid oak posts for maximum strength. They are mounted on metal feet or concrete-set brackets to prevent moisture damage and rot, ensuring long-term stability in all weather conditions.

Competitors often rely on 100 × 100 mm or 120 × 120 mm posts, but we use a minimum of 140 × 140 mm solid oak posts. Smaller posts cause problems:

Larger posts provide far better strength, stability, and structural integrity, making the entire staircase safer and longer-lasting.

At Timber Solution, we prioritize quality by offering larger-sized oak beams for our staircases. Unlike many competitors who use smaller beams and charge more, we focus on robust solutions that guarantee long-lasting strength and stability. Choosing our oak staircases means investing in a durable structure designed to withstand the test of time, providing exceptional value without compromising quality. This commitment to excellence ensures that your outdoor staircase not only looks beautiful but performs exceptionally well.

| Included To Your Oak Purchase: | ||

| Uprights | mm | 150 x 150 |

| Treads | mm | 50 x 250 |

| Risers | mm | 30 x 70 |

| Handrails | mm | 100 x 100 |

| Spindles | mm | 50 x 50 |

| Strings | mm | 75 x 250 |

| Landing boards | mm | 32 x 150 |

| Stability braces | mm | 50 x 150 |

| Joists | mm | 50 x 150 |

| Posts End Cut | mm | Free |

| Kiln Dried Oak Dowels | mm | Diameter 16 |

| What’s available as extras? | ||

| Delivery | Extra | |

| Instalation | Extra | |

| Chamfers | Extra | |

| Brace B2 – 9 | Type | Extra |

| Concealed Post Base – CPT66Z | Extra | |

| Tailor The Frame To Be Up To 225 mm Thick | ||

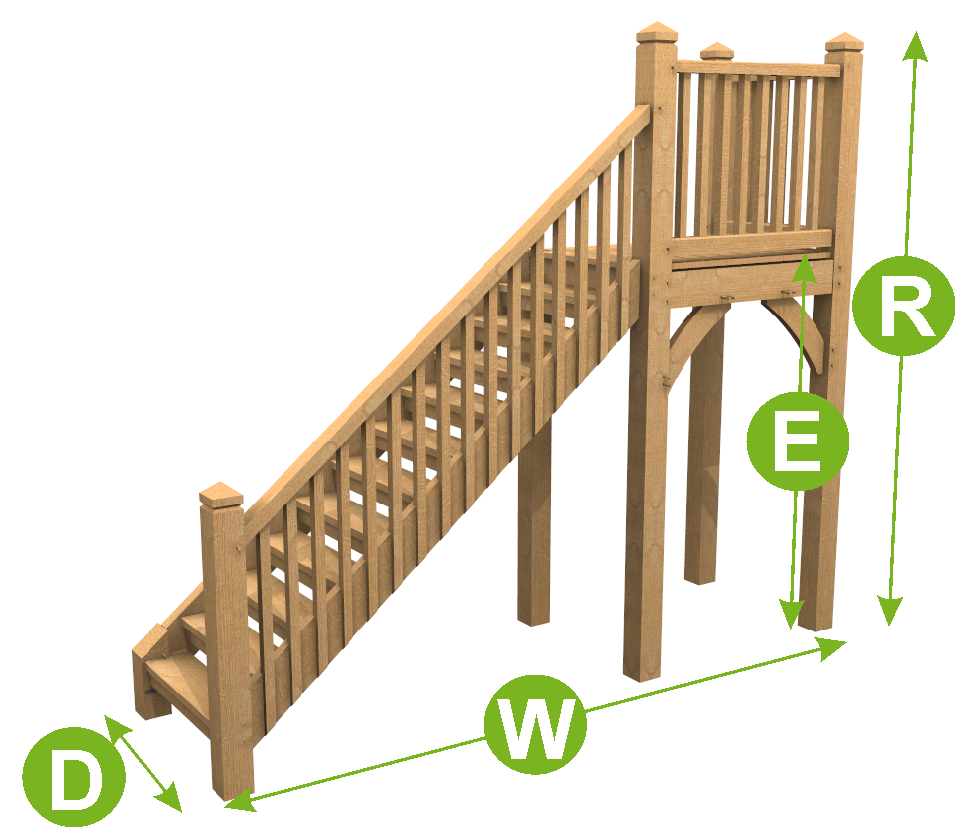

Please, provide us with information on what is required for pricing and design.

We will prepare a price offer and get back to you with an offer and 3D renders for free of charge.

If you have your own sketches, architectural drawings or photos from the internet, please attach below, it will help us with design and pricing.