| Materials | Price inc VAT | Lead Time |

|---|---|---|

| Oak | 3570 £ | |

| Douglas fir | 3420 £ | |

| Treated spruce | 3320 £ |

Available on back-order

We Offer:

If you’ve ever worked with green oak – whether in beams, peergola, gazebo, truss – you’ll know it has a life of its own. Freshly cut oak is full of moisture, and as it dries it shrinks, twists, and develops cracks. This natural movement often leaves people asking: “Can I just use a timber filler to fix the cracks in green oak?

The short answer: no, not if the oak is still green. Why Filler Doesn’t Work on Green Oak

High moisture content. Green oak can contain 60–80% water. As it dries, it will shrink significantly. Any rigid filler will simply crack and fall out.

Movement and checking. Cracks in green oak are natural and part of the seasoning process. They don’t usually weaken the timber.

Tannin staining. Oak is rich in tannins, which can react with some fillers and leave dark stains.

Recomendation. Leave it alone. Traditional oak framing is designed to move. Cracks and splits are expected, even celebrated, as part of its character.

Wait to fill. Let the oak season for at least 12–24 months before attempting filler or resin repairs. READ MORE ABOUT RESIN

Design for movement. In construction, joints and details should allow oak to move naturally without forcing repairs.

Best to wait until the oak has dried before using fillers or resins.vUsing filler on green oak is usually a waste of time. Let the oak dry, embrace the natural cracks, and only use filler later if absolutely necessary.

Photo 1. A close-up of a corner joint in a green oak post. A filler has been applied into a surface crack, but it is already pulling away from the timber. The surrounding wood shows natural shrinkage cracks, highlighting how movement in green oak causes fillers to fail.

Photo 2. The end grain of a green oak beam with large radial cracks. A filler has been applied in the centre, but it is breaking apart and separating from the wood. This clearly shows that fillers cannot cope with the significant shrinkage and movement of green oak during drying.

Damaged or severely split beams are inspected at the factory and replaced at no extra cost. If beams split on site, we will also replace them.

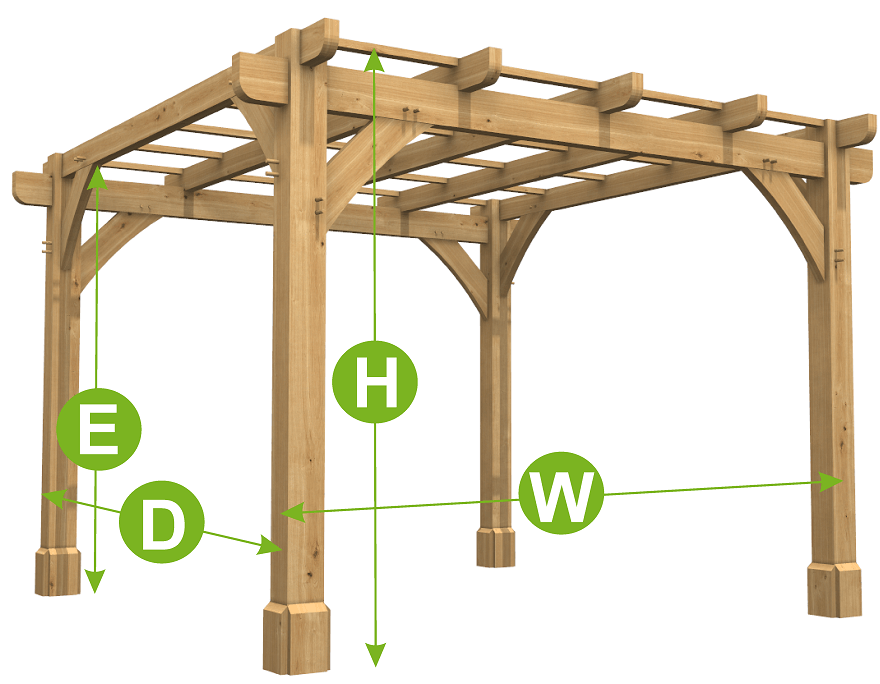

| Breeze Pergola Supplied – Included | ||

| Uprights | mm | 145 x 145 |

| Top Plates | mm | 75 x From 145 |

| Joists | mm | 60 x 140 |

| End Beam Cut | Type | A1 – 20 |

| Brace B1 | mm | 50 x 150 |

| Lattice | mm | 30 x 50 |

| Kiln Dried Oak Dowels | mm | Diameter 16 |

| Breeze Pergola Extras | ||

| Brace B2 – 9 | Extra | |

| Staddle Stones – Flat or Taper | Extra | |

| Concealed Post Base – CPT66Z | Extra | |

| Custom Wall Systems D1-14 | Extra | |

| Chamfers for Beams Larger than 165 mm | Free | |

| Fixings ( screws, nails, etc ) | Extra | |

| Delivery | Extra | |

| Tailor The Frame To Be Up To 225 mm Thick | ||

Please, provide us with information on what is required for pricing and design.

We will prepare a price offer and get back to you with an offer and 3D renders for free of charge.

If you have your own sketches, architectural drawings or photos from the internet, please attach below, it will help us with design and pricing.